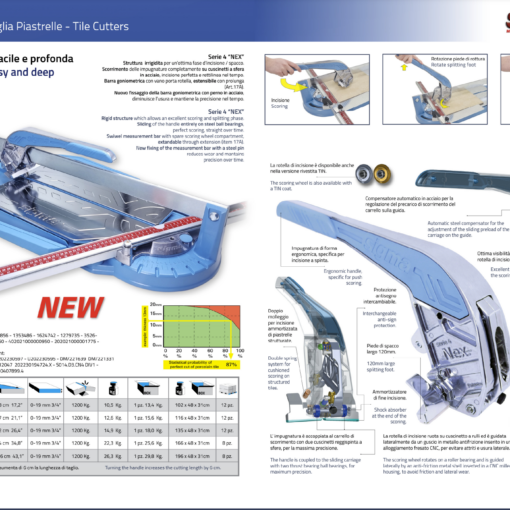

Sigma Art4DN Tile Cutter 95cm – SERIES 4 “NEX” PUSHING INCISION

New Series 4 UP handle models with traction engraving, practical and fast for cutting tiles.

Maximum cutting length: 950mm

Maximum cutting thickness: 19mm

Maximum diagonal cut: 672mm

– Pushing incision, easy and deep with minimum effort, perfect for rough, thick and large tiles.

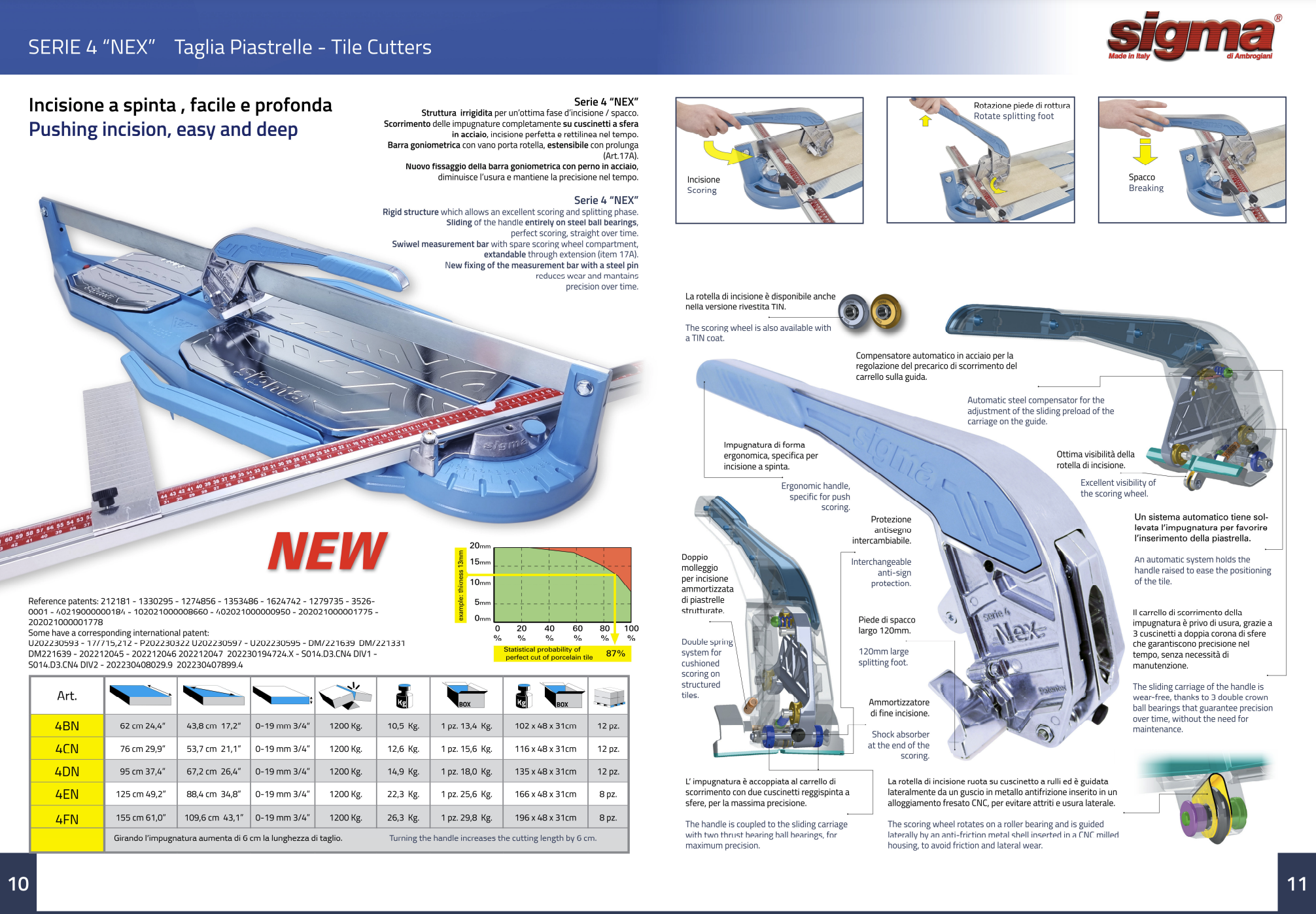

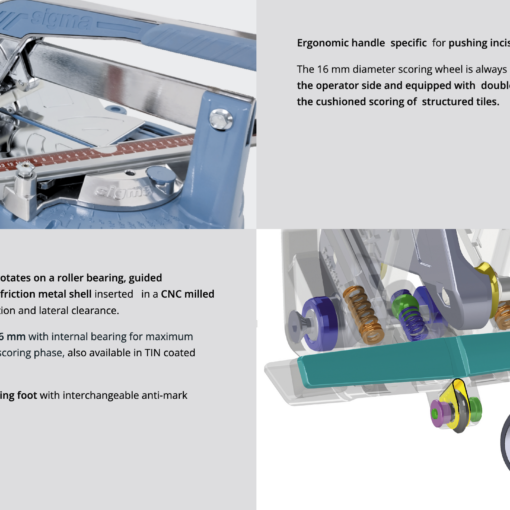

– Ergonomic handle specific for pushing incision.

– The 16 mm diameter scoring wheel is always clearly visible on the operator side and equipped with double suspension for the cushioned scoring of structured tiles.

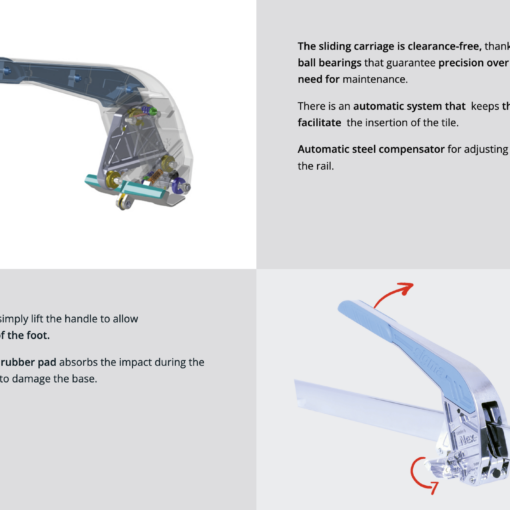

– The scoring wheel rotates on a roller bearing, guided laterally by an anti-friction metal shell inserted in a CNC milled holder,to avoid friction and lateral clearance.

– Wheels diameter 16 mm with internal bearing for maximum smoothness in the scoring phase, also available in TIN coated version.

– 120 mm wide splitting foot with interchangeable anti-mark protection.

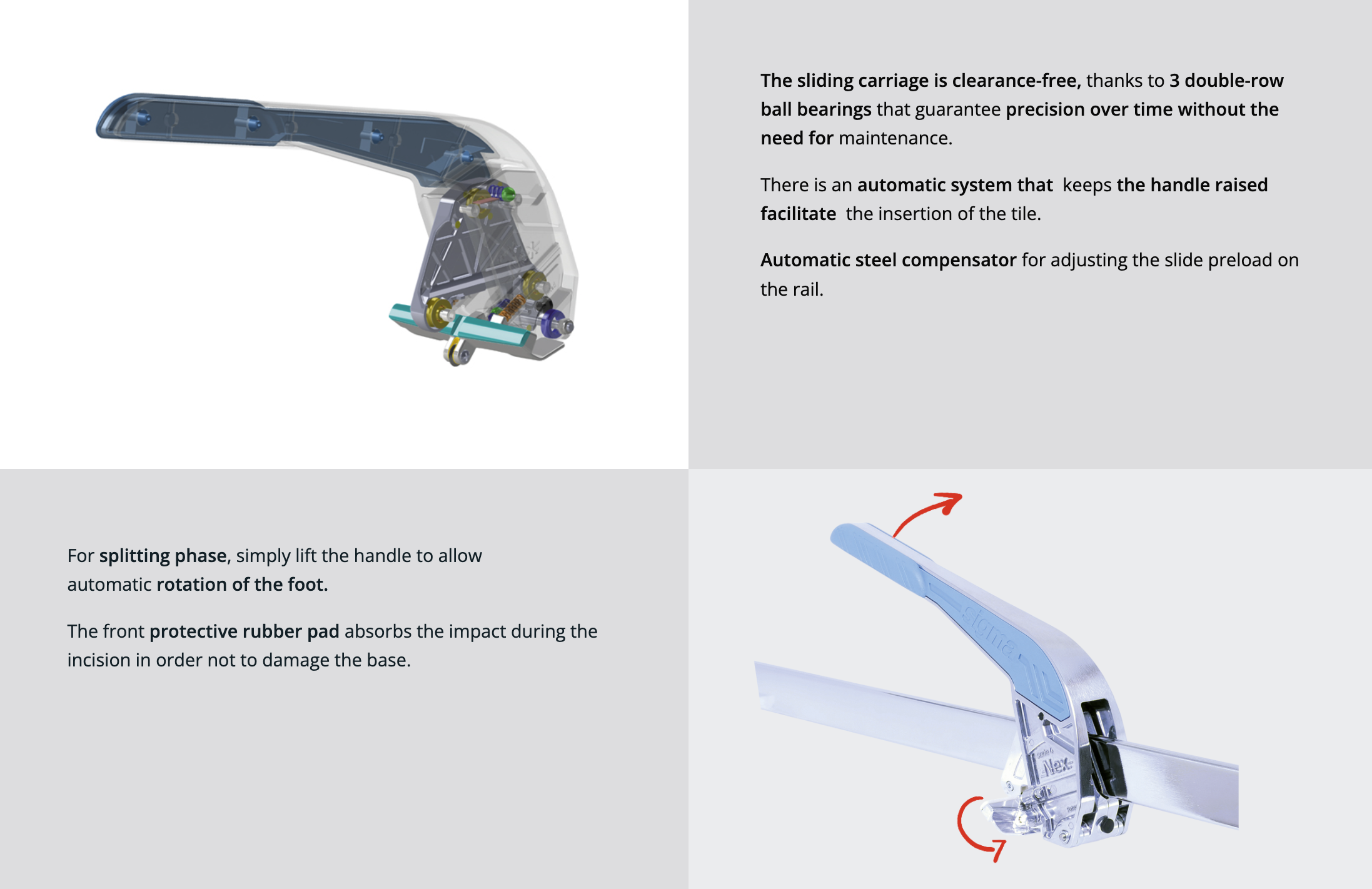

– The sliding carriage is clearance-free, thanks to 3 double-row ball bearings that guarantee precision over time without the need for maintenance.

– There is an automatic system that keeps the handle raised facilitate the insertion of the tile.

– Automatic steel compensator for adjusting the slide preload on the rail.

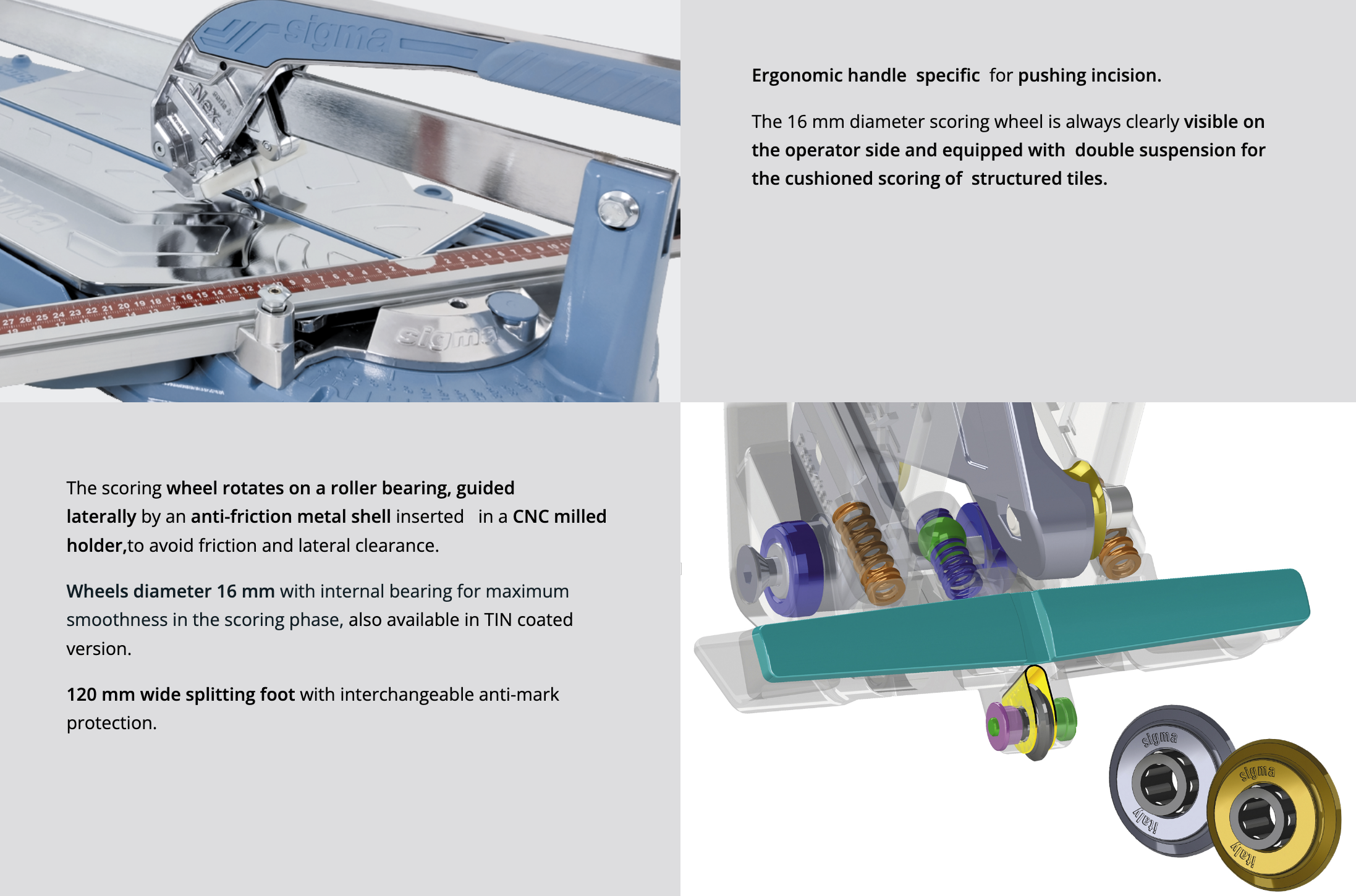

– For splitting phase, simply lift the handle to allow automatic rotation of the foot.

– The front protective rubber pad absorbs the impact during the incision in order not to damage the base.

– The 16 mm diameter scoring wheel is always clearly visible on the operator side and equipped with double suspension for the cushioned scoring of structured tiles.

– The scoring wheel rotates on a roller bearing, guided laterally by an anti-friction metal shell inserted in a CNC milled holder,to avoid friction and lateral clearance.

– Wheels diameter 16 mm with internal bearing for maximum smoothness in the scoring phase, also available in TIN coated version.

– 120 mm wide splitting foot with interchangeable anti-mark protection.

– The sliding carriage is clearance-free, thanks to 3 double-row ball bearings that guarantee precision over time without the need for maintenance.

– There is an automatic system that keeps the handle raised facilitate the insertion of the tile.

– Automatic steel compensator for adjusting the slide preload on the rail.

– For splitting phase, simply lift the handle to allow automatic rotation of the foot.

– The front protective rubber pad absorbs the impact during the incision in order not to damage the base.

Made in Italy